We are one of the leading manufacturer, exporter and supplier of best quality Ball Valves in India Mumbai. We are a well-known and reliable company that is develop a well functional and spacious infrastructural unit where we manufacture these products in an efficient way. We are a renowned firm that is manage under the supervision and have gained huge client across the nation. A ball valve has a quarter turn spindle connected to a ball inside the valve. The ball has a hole, or port, through the middle so that when the port is in line with both ends of the valve, flow will occur. When the valve is close, the hole is perpendicular to the ends of the valve, and flow is block. The handle place lets you see the valve's place. On a floating ball type, the upstream pressure the ball against the seat, giving a tight shut off. At the Tunisian mount type, the ball is fixe; Seat rings receive seat sealing action through a working springs, as the pressure of pressure increases the seat rings against a fluid pressure ball. Ball Valves are Strong enough & Usually work to do the perfect shutoff even after years of No use. Therefore Ball Valves are Perfect Choice for Shutoff Application & are often preferred to globe & Gate valve for this purpose, especially in smaller size.

Ball valves are quarter-turn, straight-through valves that have a round closure element with matching rounded seats that allow uniform sealing stress. The valve gets its name from the ball that rotates to open and close the valve. Ball valves used in situations where tight shut-off is compulsory. They are wide duty valves, able to transfer gases, liquids and liquids with suspended solids. A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball's hole is in line with the flow and closed when it is pivot 90-degrees by the valve handle. The handle lies flat in alignments with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status. Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. The most common design is the "floating ball design". The ball is remove in the media and held in place by two sealing rings. Some high-quality valves have a "trunnion ball design". The ball is help at the top and bottom to make less the load on the valve seats. These qualities make them an excellent choice for shutoff and control applications, where they are often preferred to gates and globe valves, but they lack their fine control in throttling applications. Long life and safe operation in tough services, from cryogenic to highly corrosive fluids these are the hallmarks of our comprehensive and respected ball valve portfolio. Maximum safety and environmental protection are the driving factors in every design, achieved through corrosion-resistant materials, fire-safe testing, blowout-proof stems and tight shut-off features.

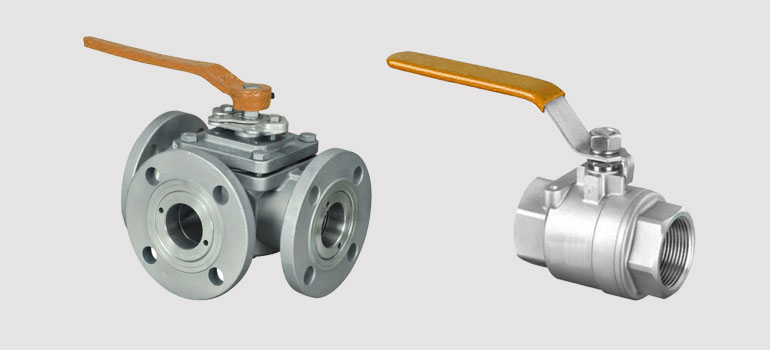

Global customers can fulfill requirements from dozens of configurations built to a full range of international design and performance standards. The ball valve's ease of operation, repair, and versatility lend it to extensive industrial use, depending on design and materials used. Valve bodies develop from metal, plastic, or metal with a ceramic, floating balls are often chrome plated for durability. Safety is the number one concern when engineers specify a vented ball. A ball valve should not confused with a "ball check valve", a type of check valve that uses a solid ball to prevent undesired back flow. Other types of quarter-turn valves include the butterfly valve and plug valve and freeze proof ball valve. The most common ball valves are consider the two-way, which allows flow to travel linearly from the inlet to the exit. We take this opportunity to introduce ourselves as a leading industrial unit manufacturing various types of Ball Valves Manufacturer the brand name of Novelty Power. Novelty Power stainless steel ball valve in investment casting is purely and solely the total concept of Novelty Power in India. It is a brand name what people today trust upon, because it is not merely a brand name but commitment to quality, reliability, proven performance and service. Furthermore, the three-way and four-way ball valves allow for flow to travel in multiple directions, including 90-degree angles.

There are four general body styles of ball valves like fully welded, three-piece body (also called as side/end-entry), split-body, and top-entry. The difference is base on how the pieces of the valve are manufacture and assembled, but the valve operation is the same in each type. Each design has its benefits. The compact, spherical design also eliminates body flanges, thus reducing overall size and leak paths. On a trunnion mounted type, the ball is fixe, seat sealing action is achieve by thrust of springs acting on the seat rings, as the pressure increases the fluid pressure pushes the seat rings against the ball. Ball Valves are Strong enough & usually work to accomplished the perfect shutoff even after years of no use. Therefore Ball Valves are Perfect Choice for Shutoff Application & are often preferred to globe & Gate valve for this purpose, especially in smaller size. However, standard ball valves do not offer the fine control that perhaps necessary in throttling applications, ball variations are available for control purposes. The unrestricted bore in full-bore ball valves make them ideal for hot tapping and digging. Being a quarter turn from fully open to fully closed, and having a relatively low operating torque, ball valves can readily actuated for remote operation.